We are now facing crisis in supply of Printed Circuit Boards, impacting the price and lead-time.

To understand better the root cause, sharing the information we have compiled for your reference and study. Will keep you updated as we get more information.

The primary raw material for Printed Circuit Boards is the Copper Clad laminates (CCL)

Copper clad laminates (CCL) are made up of Copper foil + Glass fiber + Resin

The break up of the raw material costs as percentage of CCL, would be 30-50% towards copper foil, 24-40% towards Glass Fiber and 25-30% towards Resin.

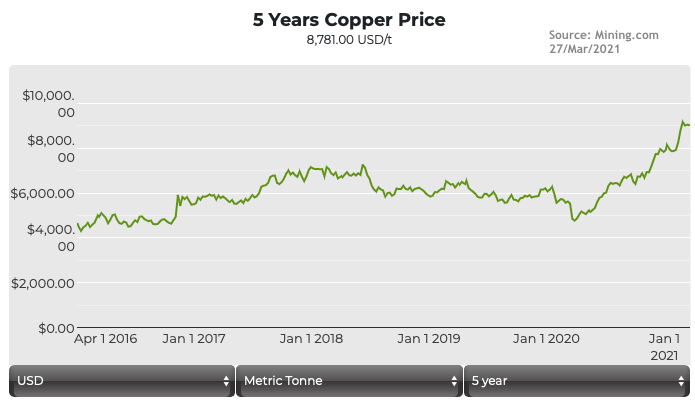

Copper

- In 2020 copper output from the mines have had a year-on-year drop, due to Covid related issues.

- Global annual copper demand around 28 million tonnes in 2020, expected to grow by 2030 to a 38 million tonnes annually.

- Bloomberg reports, a leading metals trader predict Copper could surge above a record to $12,000 a ton in 18 months on new demand from green initiatives

- On the longer horizon, declining rate of copper deposit discovery poses a long-term threat to copper supply

Copper Foil

- Demand for copper foils has increased for e-vehicles battery production.

- Copper coil factory repurposed their production to maximize SQM output for light weight foils 1oz/35micron & less used for lithium battery production

- There is a complete breakdown in supply for heavy copper foils 2oz / 70 micron and above.

- Coil foil capacity utilization at 99% for CCL and PCB

- With the forecast growth for battery demand, long lead-times, and high investments costs to increase copper foil manufacturing capacity, this situation is unlikely to ease given the policy statements and green agendas of most governments for the coming 5-10 years

Glass fiber & resin.

- High demand for epoxy resins for green energy applications (wind turbine blades)

- High growth in consumer and green energy applications is also pushing up glass yarn and glass fabric prices and limiting availability.

- Glass fabric manufacturers tend to follow the demand for those materials which have lower quality demands and command higher market prices, than those demanded by the PCB industry.

- Two major explosions at epoxy resin plants Guodu Chemical Resin Plant followed by explosion at Suzhou Xingya plant, interrupted the supply of resin

- Fire at LG Chemical Yeosu plant in South Korea, interrupting the production of ethylene and propylene.

- The glass cloth supply are primary controlled by Nitto Boseki and a few other chemical manufacture in Japan.

- In July 2020, the Nitto Boseki’s plant was damaged by fire leading a surge in prices into 2021, as PCB manufacturer bid higher to secure priority allocation of the product supply.

- Due to explosion, local authorities have increased the safety audits at epoxy resin manufacturers and other raw material suppliers. Due to the increased audits, material production has decreased and worsened the supply situation.

- Due to the atmospheric emission reduction requirements, some epoxy resin companies cannot operate at full capacity.

- Shortages and significant (60%) price hikes for CCL manufacturers.

- CCL manufacturers expect that this trend will cause laminate shortages, particularly for rigid materials.

Suppliers

China based copper foil suppliers have been more aggressive on price increase, with Guangdong Chaohua Technology increasing price by 30% in March.

Taiwan based copper foil suppliers including Co-Tech and Nan Ya plastics are under pressure to increase prices.

Due to on-going crisis, it is reported that laminate vendors ITEQ and Shengyi have stopped supply of laminate for 2 layer PCB.

Kingboard, Elite Material, Iteq, Taiwan Union Technology and Ventec International increased prices for some specific product items before the Lunar New Year holidays.

Further increases are expected later in 1H21.

{Update 30/3/21} – Taiwan-based CCL makers including Nan Ya Plastics, Iteq and Taiwan Union Technology (TUC) will raise their quotes by 15-20% starting April

New Investments

A bright light is that two of the largest Copper Foil manufacturers Co-Tech and Nan Ya have released plans to build new plants.

Co-Tech investment of USD 145M is estimated to bring in additional annual capacity of 10,800 tons by 2Q23. Co-Tech copper foils are used for high frequency/speed servers board including for Intel and AMD.

Nan Ya’s is bringing in additional new capacity of 18,000 tons of copper foil at its Southern Taiwan plan. The new production line will be for delivery for lithium-ion battery and automotive PCB market.

This article can also found on:

https://www.linkedin.com/pulse/crisis-printed-circuit-board-supply-karuna-karan/